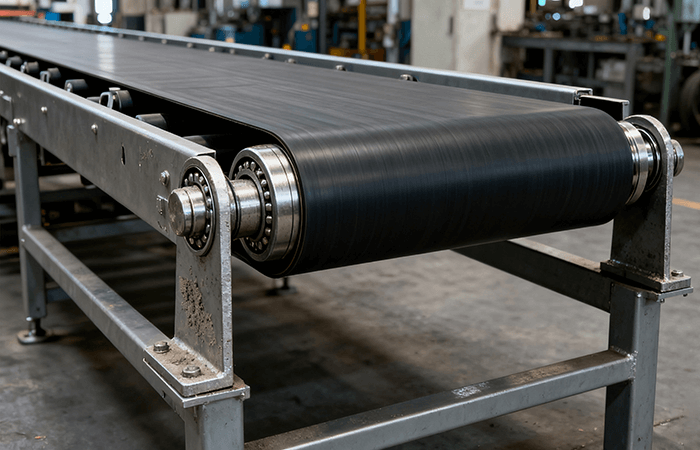

En tant que composant essentiel des équipements lourds tels que les bandes transporteuses de quai, la sélection et l'entretien des roulements à rouleaux auto-aligneurs ont un impact direct sur l'efficacité opérationnelle et la durée de vie de l'équipement. Cet article analyse les principaux aspects techniques et pratiques des roulements à rouleaux à alignement automatique. roulements de rouleaux de convoyeurs dans le contexte des applications de quai.

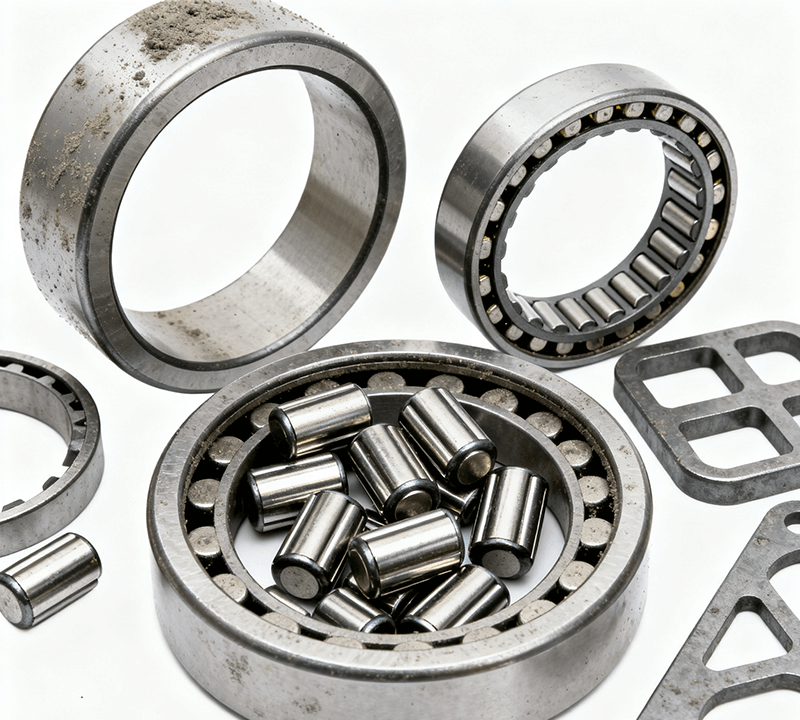

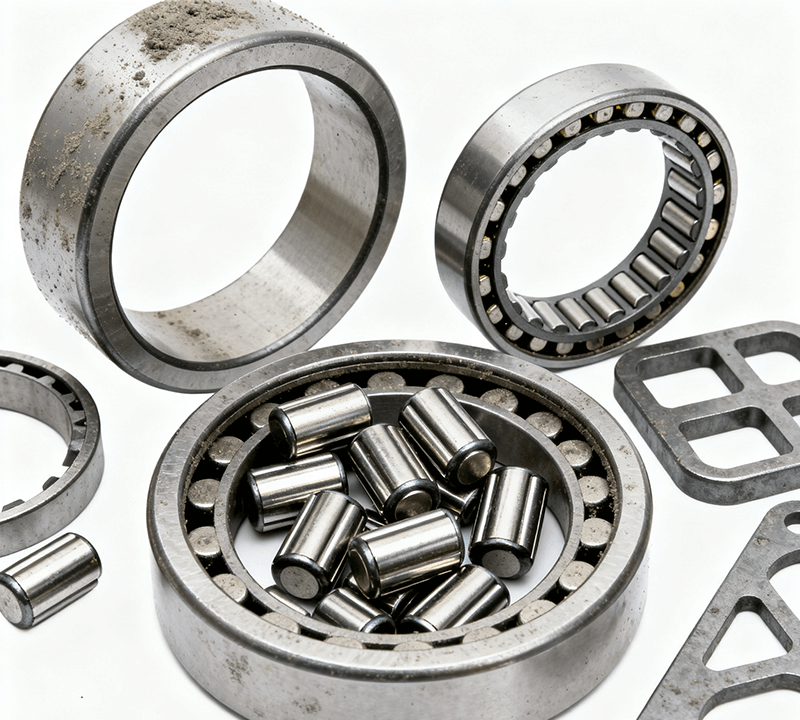

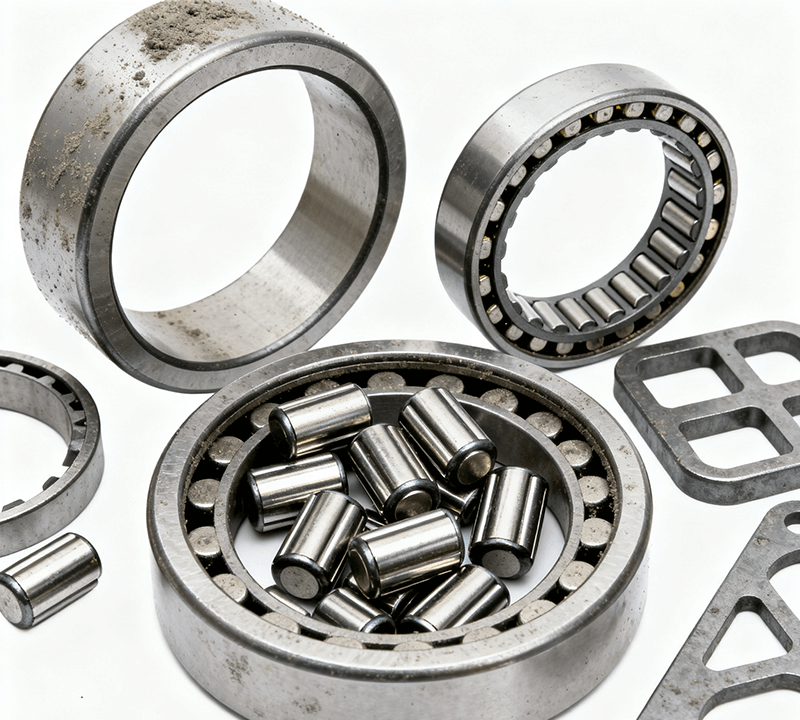

Les roulements à rouleaux pour convoyeurs possèdent une excellente capacité d'auto-alignement, compensant efficacement les écarts d'installation potentiels des bandes transporteuses et la déformation de l'arbre pendant le fonctionnement. Dans les conditions de travail continu à haute intensité des quais, ces roulements améliorent de manière significative les performances globales de l'entreprise. capacité de charge en optimisant la répartition des contraintes de contact entre les rouleaux et les chemins de roulement. Lors de la sélection des roulements, il est recommandé de choisir des roulements à rotule. roulements à rouleaux avec des structures d'étanchéité pour mieux résister aux conditions difficiles des docks, telles que l'humidité et la poussière.

Contenu

Les roulements à alésage carré trouvent de nombreuses applications dans la fabrication. Nous présentons ci-dessous leurs principales caractéristiques et utilisations. Les r...

Les roulements à billes en carbure de tungstène, communément appelés billes en acier au tungstène, sont des roulements à billes et à rouleaux fabriqués...

En tant que composant essentiel d'équipements lourds tels que les bandes transporteuses de quai, la sélection et l'entretien des...