Square bore bearings find extensive applications in manufacturing. Below we highlight their key features and uses.

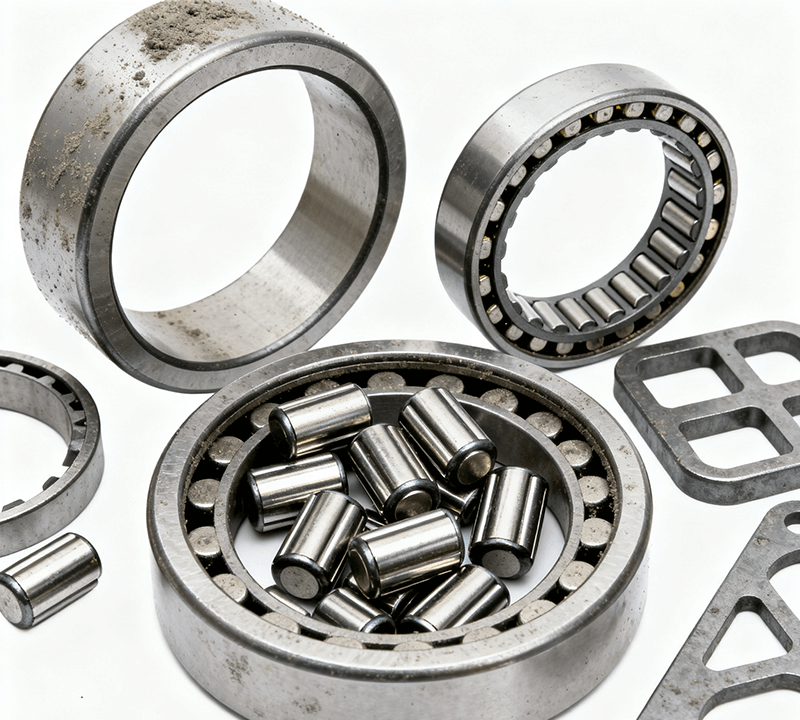

Structure and Principle: Square bore bearings typically consist of an inner ring, outer ring, cage, and rolling elements. Their distinctive feature is the square mounting hole in the inner ring. This design facilitates precise alignment and quick installation with square shafts, enabling direct torque transmission while eliminating potential slippage issues common in traditional cylindrical bore bearings.

Performance Characteristics: Square bore bearings feature a simple structure with low friction, delivering outstanding performance under high-speed rotation and heavy-load conditions. Compared to traditional wentellagers, they significantly reduce operational noise and friction loss while offering higher laadcapaciteit and extended service life.

Application Areas: Square bore bearings are widely used in various mechanical equipment. In agricultural machinery such as disc harrows, seeders, and harvesters, they are extensively employed due to their ability to withstand heavy loads and harsh working environments. Additionally, they find broad application in industrial machinery, automated equipment, conveying systems, and transmission mechanisms.

Installation and Maintenance: Before installation, ensure both the bearing and mounting surface are clean to prevent foreign object ingress. Furthermore, based on the bearing’s operational requirements, apply appropriate lubricating oil or grease at regular intervals and avoid overloading to extend its service life.

What is the difference between square bore bearings and standard bearings?

The core distinction between square bore bearings and standard cylindrical bore bearings lies in the shape of the inner bore. This difference extends to installation compatibility, torque transmission, and application scenarios, as detailed below:

Inhoud

Square-Bore Bearings: Square inner bore requires square shafts for precise geometric fit without additional locating components.

Standard Bearings: Round inner bore represents the most common standard design, compatible with conventional cylindrical shafts and serving as the universal specification in industrial applications.

Square Bore Bearings: Torque is transmitted directly through the face contact between the square bore and square shaft, eliminating slippage. This ensures high and stable torque transmission efficiency.

Standard Bearings: The circular bore contacts the round shaft via circumferential surface contact. Additional positioning structures like keyways or flat keys are required for torque transmission; otherwise, relative sliding may occur.

Square Bore Bearings: Primarily used in non-standard or specialized equipment requiring high torque transmission and zero relative shaft-bearing slippage. Examples include agricultural machinery (transmission components in seeders and harvesters), small conveying equipment, and rotating structures in hand tools.

Standard Bearings: Applicable across the vast majority of industrial scenarios—from motors, machine tools, and automotive chassis to home appliances and precision instruments—serving as highly versatile fundamental components.

Square-hole bearings: Their non-circular inner bore design increases manufacturing complexity compared to circular bores. More intricate molds and production processes result in higher per-unit costs, typically involving custom or small-batch production.

Standard bearings: Circular inner bores benefit from mature manufacturing techniques and high standardization, enabling large-scale mass production. This leads to lower costs and greater ease of procurement and replacement.

Square-Bore Bearings: Installation requires precise alignment between the square shaft and bearing bore, achievable through interference or transition fits. Removal necessitates specialized tools to prevent bore wall damage. Maintenance requirements are largely consistent with standard bearings, including regular lubrication and cleaning.

Standard Bearings: Installation and removal are straightforward. Supporting components like shafts and bearing housings are readily available, and maintenance procedures are more standardized.

Lagers met vierkante boring vinden uitgebreide toepassingen in de productie. Hieronder belichten we hun belangrijkste kenmerken en toepassingen. Str...

Wolfraamcarbide kogellagers, algemeen bekend als wolfraam stalen kogels, zijn sferische en rollagers vervaardigd...

Als kernonderdeel van heavy-duty apparatuur zoals dock transportbanden, is de selectie en het onderhoud van zelfuitlijnende...