In the process of industrial facilities maintenance, many practitioners will encounter such a problem: bearing wear and tear, whether to choose to replace the new or repair treatment? Bearing refurbishment In fact, bearing recycling (also known as bearing repair and regeneration), has long been widely recognized as an efficient, affordable and environmentally friendly response to the global manufacturing sector.

What is bearing reconditioning?

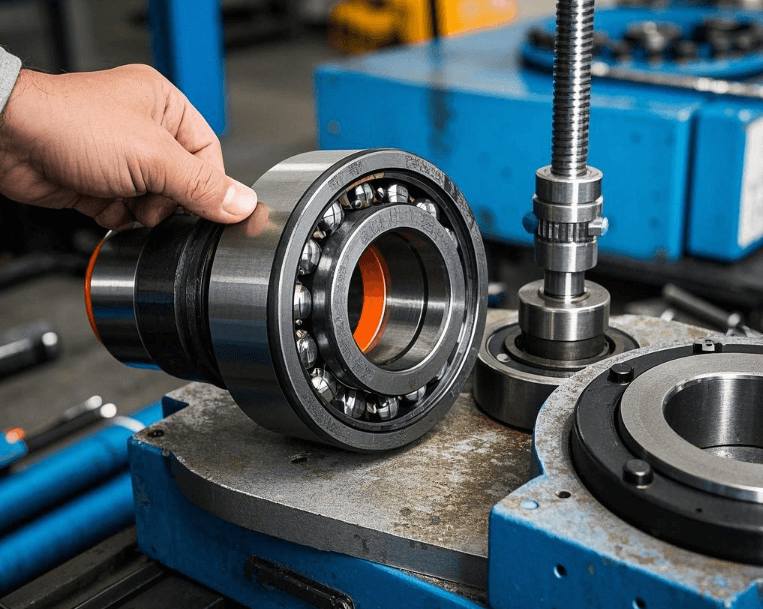

Bearing recycling is the process of restoring the performance of bearings that have been running for a certain period of time, and are subject to wear and tear or surface fatigue, to a nearly new state with the help of a series of processes such as professional testing, cleaning, repairing and secondary treatment. Reconditioned bearings are able to run continuously and stably in the equipment, significantly reducing the number of replacements.

Which bearings are suitable for remanufacturing?

Not all bearings are suitable for recycling, the following tipuri de rulmenți are particularly suitable:

Large and special specification bearings (such as rolling mill bearings, wind power spindle bearings, etc.)

Imported bearings and non-standard customized bearings, which have a long purchasing cycle and high price

No serious damage to the appearance, no serious cracks or deformation of the inner and outer rings of the bearing

What is the process of bearing recycling bearing refurbishment ?

Inspection and evaluation: using professional equipment to inspect the size, accuracy and fatigue condition of the bearings

Cleaning and decontamination: thoroughly remove the oil and impurities inside the bearings

Surface restoration: using polishing, grinding, plating, heat treatment and other means

Component replacement: if the rolling element and cage are damaged, then they will be replaced

Assembly and testing: reassembled in accordance with the standards, and test the rotational accuracy and load performance

Significant advantages of bearing rebuilding

Savings: 40% – 70% cost reduction compared to purchasing new bearings

Reduced downtime: quick reconditioning, no need to wait for a long time for new bearings to arrive

Environmentally friendly and energy-saving: Reduced material consumption and waste disposal, in line with the trend of carbon neutrality

Reliable quality: Professionally reconditioned bearings are comparable to new ones in terms of performance, and are stable and safe to operate

Bearing refurbishment is not a stopgap solution

It is important to stress that bearing reconditioning must be carried out by a professional organization or a qualified person. It is important to emphasize that bearing remanufacturing must be carried out by a professional organization or qualified maintenance unit. Otherwise, not only will the purpose of prolonging the service life not be realized, but also more serious equipment failures may occur due to improper maintenance.