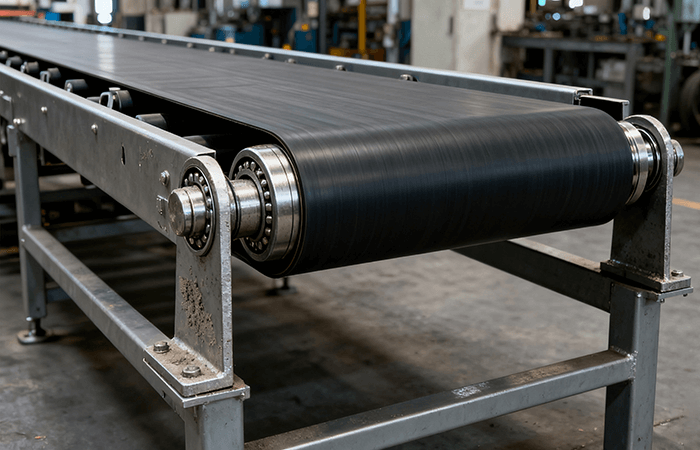

Выбор и обслуживание самоустанавливающихся роликовых подшипников, являющихся основным компонентом тяжелонагруженного оборудования, такого как ленточные доковые конвейеры, напрямую влияют на эффективность работы оборудования и срок его службы. В данной статье анализируются основные технические и практические аспекты роликовые подшипники конвейера в контексте доковых приложений.

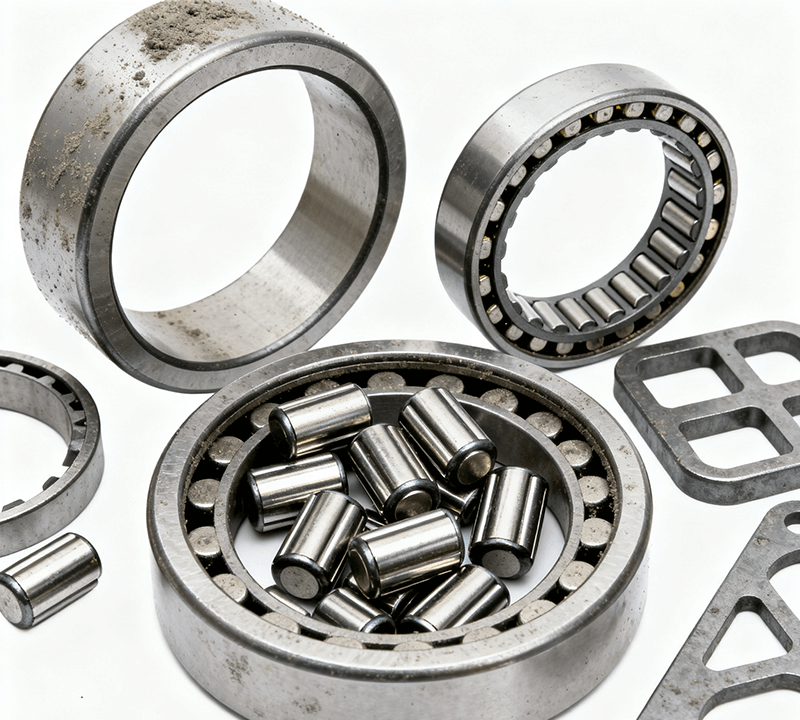

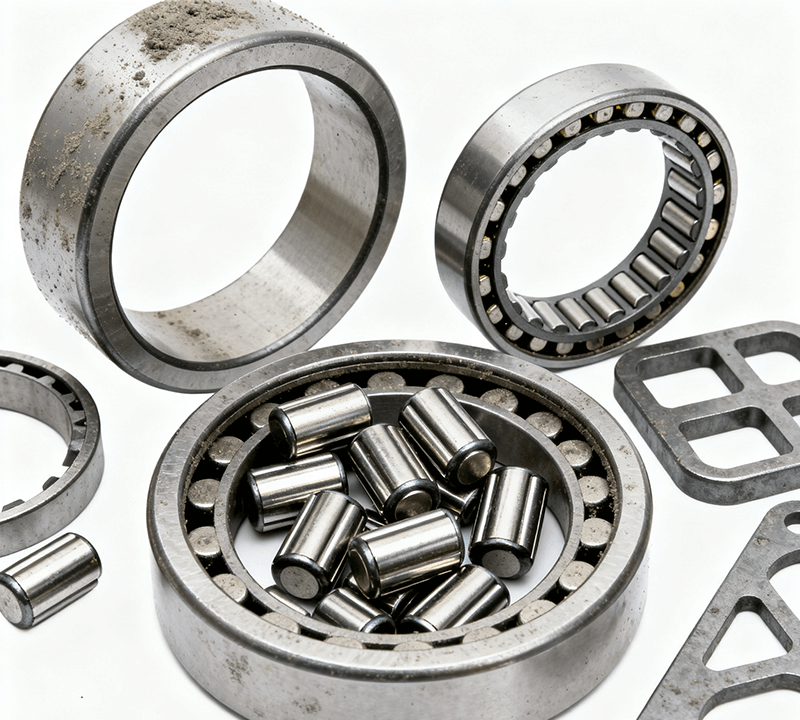

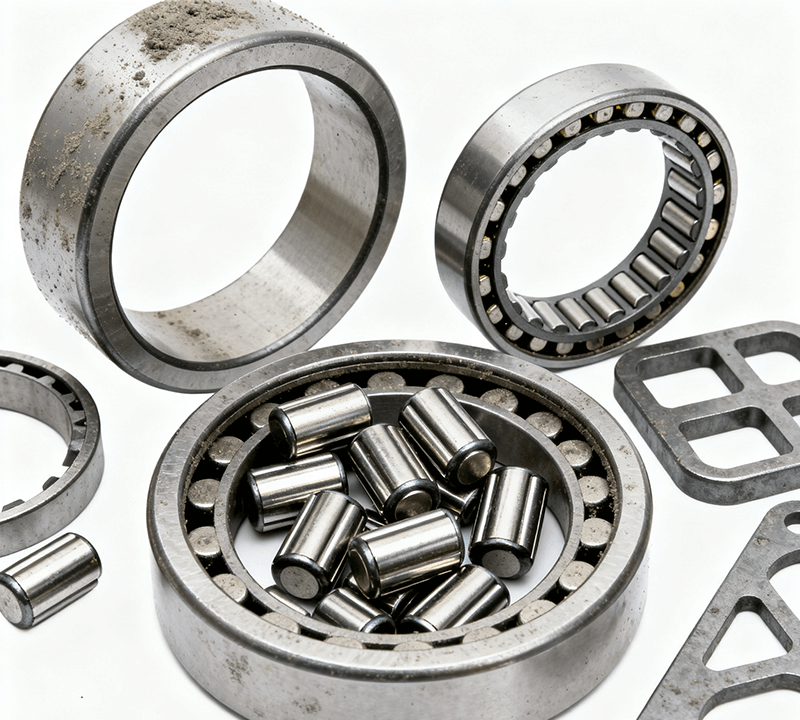

Конвейерные роликоподшипники обладают превосходной способностью к самоустановке, эффективно компенсируя возможные отклонения в установке конвейерных лент и деформацию валов во время работы. В условиях высокоинтенсивной и непрерывной работы в доках эти подшипники значительно повышают общий грузоподъёмность за счет оптимизации распределения контактных напряжений между роликами и дорожками качения. При выборе подшипников рекомендуется выбирать самоустанавливающиеся роликовые подшипники с уплотнительными конструкциями, чтобы лучше противостоять суровым условиям эксплуатации, таким как влажность и пыль.

Содержание

Подшипники с квадратным отверстием находят широкое применение в производстве. Ниже мы приводим их основные характеристики и области применения. Стр...

Шарикоподшипники из карбида вольфрама, широко известные как шарики из вольфрамовой стали, представляют собой сферические и роликовые подшипники, изготовленные...

Являясь основным компонентом тяжелого оборудования, такого как доковые конвейеры, выбор и обслуживание самоцентрирующихся...