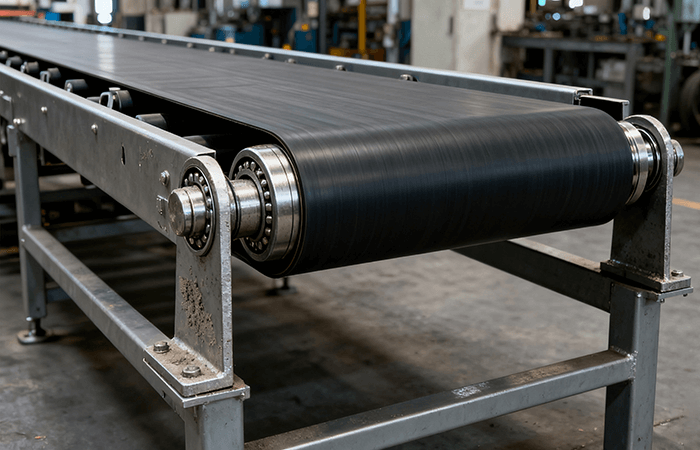

As a core component of heavy-duty equipment such as dock conveyor belts, the selection and maintenance of self-aligning roller bearings directly impact equipment operational efficiency and service life. This article analyzes key technical and practical aspects of conveyor roller bearings in the context of dock applications.

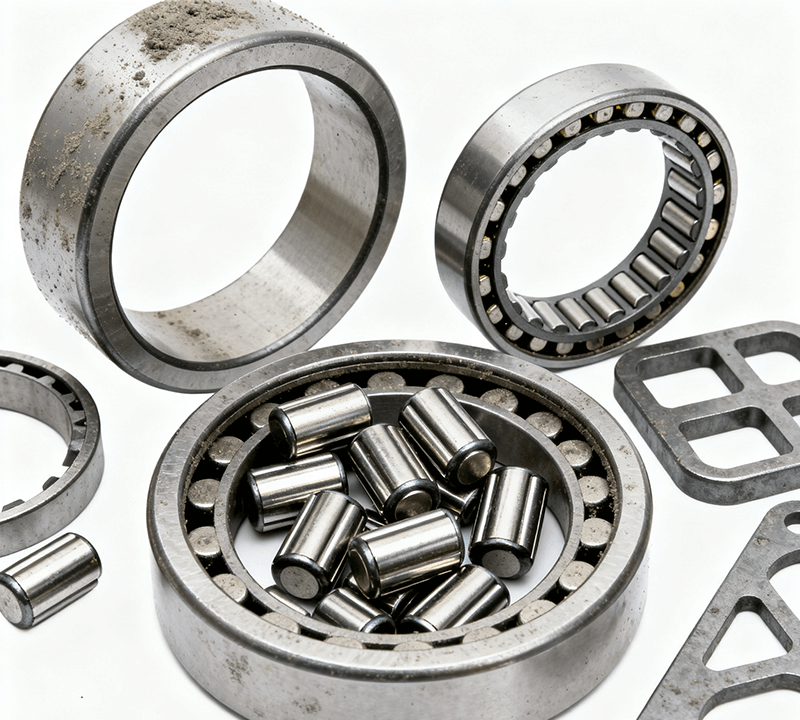

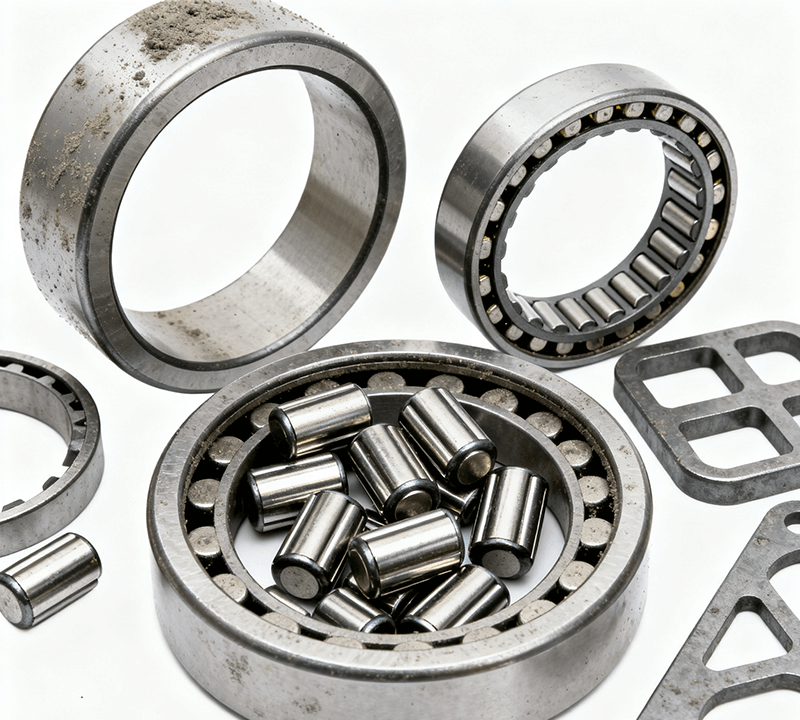

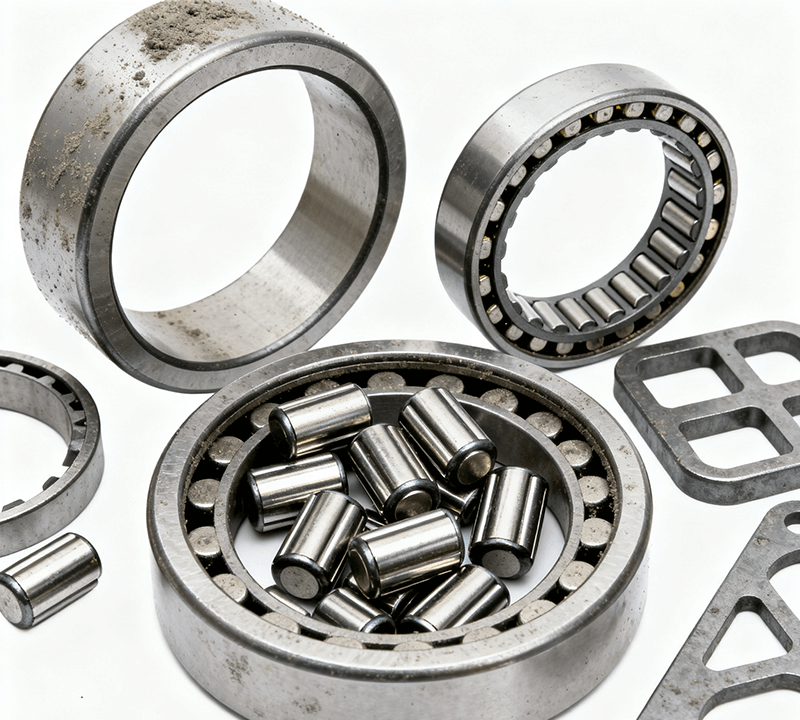

conveyor roller bearings possess excellent self-aligning capability, effectively compensating for potential installation deviations in conveyor belts and shaft deformation during operation. Under the high-intensity, continuous working conditions of docks, these bearings significantly enhance overall load capacity by optimizing the contact stress distribution between the rollers and raceways. When selecting bearings, it is recommended to choose self-aligning roller bearings with sealing structures to better withstand harsh dock conditions such as humidity and dust.

Contents

Square bore bearings find extensive applications in manufacturing. Below we highlight their key features and uses. Str…

Tungsten carbide ball bearings, commonly known as tungsten steel balls, are spherical and roller bearings manufactured…

As a core component of heavy-duty equipment such as dock conveyor belts, the selection and maintenance of self-aligning…