Eine Analyse der Merkmale und Anwendungen von sechs gängigen Lagertypen im Industriesektor

Bearings have a wide range of applications in the industrial field . Whether dealing with heavy-load working conditions or ensuring the stable operation of high-speed precision equipment, it is crucial to have a the stable operation of high-speed precision equipment, it is crucial to have a thorough understanding of the characteristics of different types of bearings.

Such an understanding serves as a key prerequisite for guaranteeing the smooth operation of mechanical systems.

The following article will detail six commonly used types of bearings and the unique roles they play in various industrial scenarios.

The orderly advancement of modern industrial production relies on the support of various types of bearings for the smooth operation of mechanical equipment. From mining, industrial manufacturing to transportation, agricultural production and other fields, bearings provide guarantees for the reliable operation of heavy-duty equipment and play an indispensable role in promoting the realization of mechanical movement and bearing the load of equipment in multiple fields.

This article will focus on six common types of bearings and their specific application scenarios, comprehensively demonstrating how they empower the efficient operation of global industry, ranging from traditional

ball bearings to more advanced roller bearing designs.

Bearings are core components in industrial equipment, and the normal operation of tens of thousands of essential items in daily life depends on bearings. As important components in the field of tribology, bearings are defined as interacting surfaces that participate in relative motion. Other components in this category include seals, piston rings, and brushes.

Bearings come in a wide variety of shapes and sizes, with each design tailored to a specific type of motion. Depending on the requirements of the overall system, as well as the load and movement mode that the equipment needs to bear, the degree of freedom of movement of the bearing will be restricted accordingly. Bearings used in different application scenarios have a variety of standardized design features.

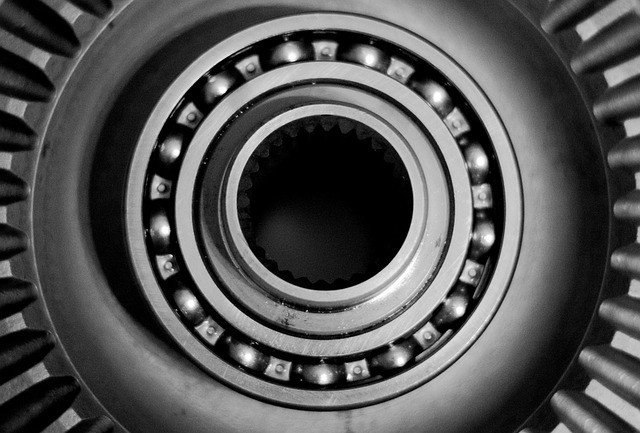

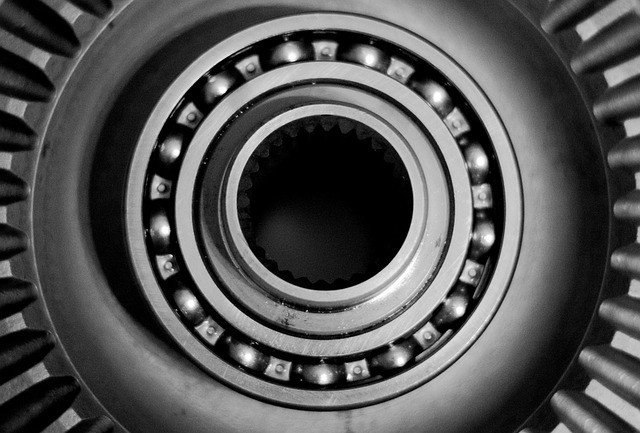

In terms of structure, a bearing is mainly composed of three parts: an inner ring, an outer ring, and rolling elements between them. The annular structures of the inner and outer rings are called “raceways”, and the rolling elements include balls, rollers and other types. In addition to these three core components, bearings are also equipped with a cage, whose function is to fix the position of the rolling elements and prevent unnecessary collision and displacement of the rolling elements.

The design goals of these components are very clear: on the one hand, to reduce friction during mechanical movement, and on the other hand, to stably support the equipment load. By preventing direct metal-to-metal contact between relatively moving parts, bearings can effectively reduce the degree of wear of components and lower equipment energy consumption. At the same time, bearings also optimize the weight distribution of the equipment, transferring the load to the housing instead of directly acting on the rotating components.

Bearings have an extremely wide range of application scenarios, from daily equipment to industrial machinery. Examples include the bogies of railway vehicles, aircraft engines, and the main shafts of wind turbines. In the industrial field, bearings are indispensable core components in machinery such as motors, gearboxes, water pumps, and conveyors, and are widely used in the daily production of multiple industries.

Fields such as manufacturing, oil and gas extraction, construction, and marine engineering all rely on heavy-duty machinery for operations. Different bearing designs also show differentiated advantages according to the application needs of different industries. For example: Thrust

Kugellagers have strong rigidity and can bear larger axial loads;

Kegelrollenlager are standard configurations in commercial vehicles, adapting to the transmission needs of vehicles; Hydrostatic bearings can provide heavy-load support for equipment by restricting the relative movement of components.

According to the structural type of bearings and the characteristics of the mechanical equipment they are adapted to, different

bearings can bring multiple advantages to industrial applications. Various industries usually adopt mature bearing designs to meet specific usage needs and adapt to different operating environments.

For instance, industrial

Kugellager are widely used in the aerospace field due to their high precision and low friction characteristics; in agricultural machinery, roller bearings are preferred for their advantage of withstanding heavy loads. When operators select suitable bearings for specific operations, they can usually obtain the following benefits:

- Improve the operating efficiency of equipment and reduce ineffective energy consumption;

- Extend the overall service life of mechanical equipment and reduce the frequency of replacement;

- Reduce the time and cost required for equipment maintenance and ensure production continuity.

In addition to the above general advantages, different industries can also enjoy the exclusive value brought by bearings:

- Mining industry: Bearings can withstand high-intensity loads and extreme working conditions, adapting to the complex operating environment of mines;

- Manufacturing industry: Bearings can ensure the design accuracy of equipment and improve the durability of mechanical components;

- Oil and gas industry: Specialized bearings can operate stably in high-pressure environments, adapting to the harsh conditions of oil and gas extraction;

- Construction industry: Bearings support equipment to achieve heavy-load operations under various working conditions and ensure construction efficiency;

- Agricultural industry: Bearings have the ability to withstand harsh environments and resist climate changes, adapting to complex field operations;

- Wind energy industry: Bearings can maintain stable performance under extreme operating conditions and ensure the continuous power generation of wind turbines.

Different types of bearings are originally designed to adapt to different application scenarios. Although the basic configuration of various bearings is similar, there are differences in the structural design of rolling elements and rings, thus forming different types of bearings. The following are six common types of bearings:

Ball bearings are currently the most widely used type of bearings, with their rolling elements consisting of a row of balls. These balls are held between metal components called “raceways”. Usually, the outer ring is fixed, while the inner ring can rotate freely with the equipment components. Due to the extremely

low friction of ball bearings, they are suitable for equipment that requires low friction and high precision, such as centrifugal pumps and railway axles.

Ball bearings have a wide range of sub-types, including

Rillenkugellager, thrust ball bearings, self-aligning ball bearings, angular contact ball bearings, etc. Different sub-types can be adapted to different load directions and movement requirements.

Roller bearings are also known as

Wälzlagers . The core difference between roller bearings and ball bearings is that roller bearings replace the balls with cylindrical rolling elements—specifically, rollers—whose width is greater than their diameter . The structural design of these rollers enables them to make full contact with the raceways of the inner and outer rings. This full-contact feature is what makes roller bearings more suitable for bearing heavy loads compared to other types. Given their ability to withstand heavy loads, roller bearings are widely applied in equipment that requires such load-bearing capacity. Typical examples include agricultural machinery, food processing equipment, and mining vehicles.

Roller bearings also have a variety of sub-types, including self-aligning roller bearings,

tapered roller bearings, needle roller bearings, cylindrical roller bearings, etc. The appropriate type can be selected according to the load type and installation space of the equipment.

Plain contact bearings have a relatively simple structural design, with smooth and flat contact surfaces and no dedicated rolling elements. This type of bearing has a high load-carrying capacity and can adapt to scenarios involving component misalignment and multi-directional movement. It is widely used in fields such as agriculture, shipping, automobiles, and construction.

The most

common type of plain bearing is the bushing. In addition, there are also two-piece bearings and solid bearings, etc. Different types can be adapted to the installation and movement requirements of different equipment.

In specific application scenarios, fluid film bearings are often used as substitutes for metal bearings. They can effectively extend the service life of key components of equipment and at the same time reduce the noise and vibration levels during mechanical operation. Although the initial purchase cost of fluid film bearings is higher than that of other types of bearings, in the long run, they can significantly reduce equipment vibration problems and lower maintenance and component replacement costs.

The

working principle of fluid film bearings is to use pressurized gas or liquid to bear the equipment load with minimal friction. Therefore, they are very suitable for equipment such as generator sets in hydropower plants, turbines, and propeller shafts of ships. According to different working methods, fluid film bearings can be divided into two categories: hydrostatic bearings and hydrodynamic bearings.

The core technology of magnetic bearings is the principle of magnetic levitation. Their operation does not rely on physical contact between components, so they have excellent wear resistance and are an ideal choice for high-speed rotating equipment. At present, magnetic bearings have been widely used in multiple fields such as power generation, machine tool processing, and natural gas transmission.

Magnetic bearings are mainly divided into two categories: active magnetic bearings and passive magnetic bearings. Active magnetic bearings generate a magnetic field through electromagnets around the shaft to achieve the levitation and control of the shaft; passive magnetic bearings use the magnetism of permanent magnets to form a stable magnetic field support.

Unlike the above five types of bearings, the classification of linear motion bearings is not based on specific structures and components, but on the limitation of their design purpose—that is, they only support unidirectional free movement. Therefore, all the

Lagerarten mentioned above can be designed as linear motion bearings according to requirements.

This type of bearing is also known as a linear guide rail. It is mainly used in equipment that requires unidirectional linear motion, such as the guide rails of machine tools, XY worktables, and roller worktables. It can provide stable and high-precision linear motion support for equipment.

When equipment exhibits abnormal vibration, increased noise, decreased precision, and other conditions, it may indicate that the bearings need to be replaced. We specialize in the production of high-quality bearings suitable for industrial scenarios. We provide a wide range of product options for mechanical equipment and heavy-load applications in various industries, including various types of

Kugellager, roller bearings, bearing housings, and sealing solutions.

If you want to improve the efficiency of your business operations and optimize equipment performance, you can learn more about our bearing products and power transmission series, and we will provide you with suitable industrial component solutions.