Diesel engine thrust bearings, Summary of Structural Principles and Adjustment Methods of Diesel Engine Thrust Bearings

Isi

The ship’s main engine drives the propeller through the coordinated action of the thrust shaft, intermediate shaft, and stern shaft. When the propeller rotates, its blades exert both circumferential and axial forces on the water. According to the principle of action and reaction, the water also exerts corresponding circumferential and axial reaction forces on the propeller blades.

The circumferential force acting on the propeller generates torque, requiring the engine’s driving torque to overcome this resisting torque. The axial force exerted on the propeller is critical, as it either becomes the thrust propelling the vessel forward or the pull causing it to move backward.

This thrust (or pull) is progressively transmitted: first through the stern shaft, then to the intermediate shaft, followed by the thrust shaft, ultimately acting upon the thrust bearing. The thrust bearing then transfers the force to the hull, propelling the vessel.

For medium-to-large low-speed diesel engines commonly used as main engines, the design and manufacturing process specifically accounts for bearing the propeller thrust. Typically, the thrust bearing is mounted on the thrust bearing housing at the stern end of the engine base. The thrust bearing housing connects to the engine base in two ways: either welded or bolted into a single unit. Its function is to transmit the axial thrust from the propeller shaft through the base to the hull, propelling the vessel forward.

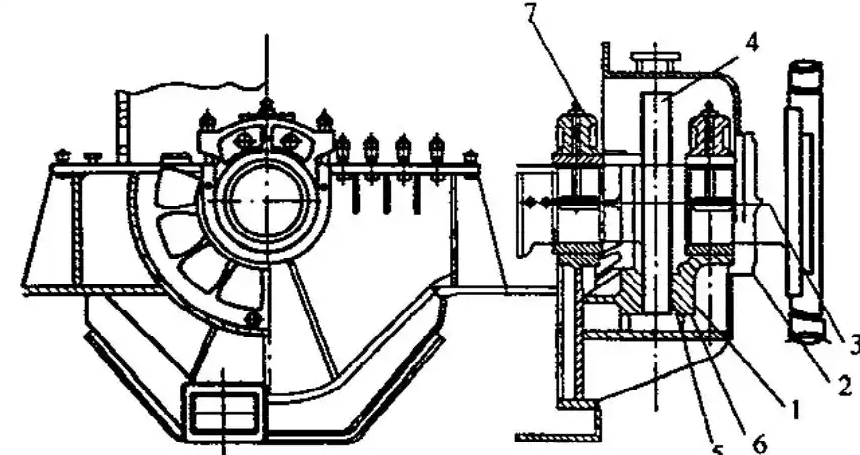

In medium-to-large diesel engines, single-ring thrust bearings are widely used, with their structure illustrated in Figure 1. The thrust bearing housing employs a welded cast steel construction and incorporates two support bearings internally, primarily bearing the weight of the thrust shaft and the main engine flywheel.

The thrust shaft is fabricated from high-quality 35 cast steel and connects to the flywheel via a tight-fitting bolt. Its central section functions as a thrust ring, engaging with the fan-shaped thrust blocks (5). This arrangement enables the thrust force on the shaft to be transmitted to the thrust bearing housing through the thrust blocks.

The thrust blocks are arranged in two concentric rings: the front ring bears thrust during forward operation, while the rear ring handles reverse thrust. Each ring is fitted with a retaining plate (7) to prevent the thrust blocks from slipping out during operation. These thrust blocks are segmented steel pieces made of low-carbon steel grade 20. Workers cast white metal onto their working surfaces. The white metal is embedded through dovetail grooves on the back of the thrust blocks, ensuring a secure fit.

The commonly used white alloy material is SbSnSbH-b tin-based bearing alloy, which bonds readily with low-carbon steel and offers excellent compatibility. Each thrust surface is equipped with eight thrust blocks to collectively bear the thrust load. Support shims of varying thicknesses are positioned behind the thrust blocks. When wear occurs, operators can replace the shims to adjust the axial clearance between the thrust ring and thrust blocks.

Personnel lubricate the thrust blocks and thrust ring by injecting lubricating oil. The support section on the back of the thrust block occupies only about half of the entire sector angle. This design allows the thrust block to oscillate slightly in place during operation, facilitating oil penetration onto the working surface and establishing an oil film.

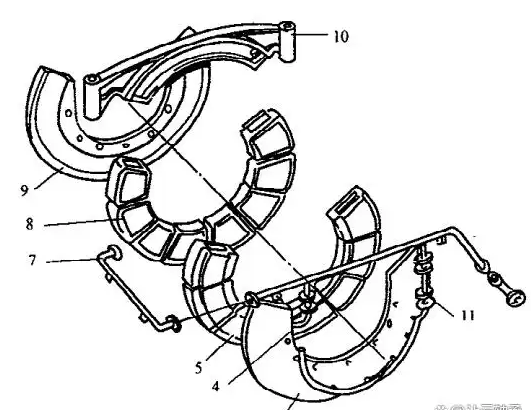

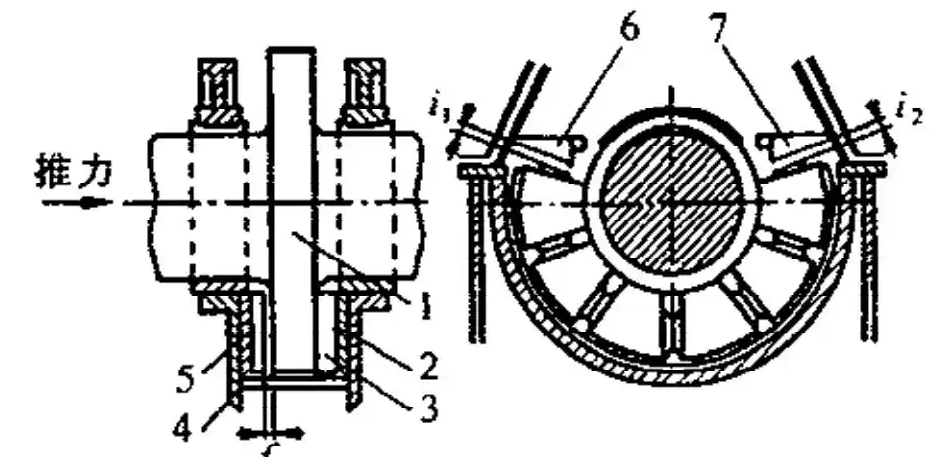

Figure 2 illustrates the construction of the thrust bearing for the L-MC/M diesel engine. The thrust shaft and crankshaft of this engine are manufactured using an integral forging process. The outer flange of the thrust ring secures the drive sprocket for the transmission camshaft, a configuration that effectively reduces the engine’s axial dimensions.

The thrust bearing primarily consists of forward thrust blocks 8, reverse thrust blocks 5, thrust plates (adjustment rings) 3 and 9, and other components. Eight forward and eight reverse thrust blocks are arranged circumferentially to form a sector covering approximately two-thirds of the circumference.

During forward operation, axial thrust generated by the propeller is transmitted through the stern shaft and intermediate shaft to the thrust ring, propelling the vessel forward against water resistance. To prevent thrust blocks from rotating with the thrust ring, personnel install locators above both forward and reverse thrust blocks for positioning.

Personnel lubricate the thrust ring using oil from the main bantalan lubrication system. To prevent oil leakage from the journal outside the engine, personnel install shaft seals on the journal. During thrust shaft rotation, the oil thrower ring 2 uses centrifugal force to expel lubricating oil splashed onto the shaft. Residual oil is scraped off by the oil scraper ring.

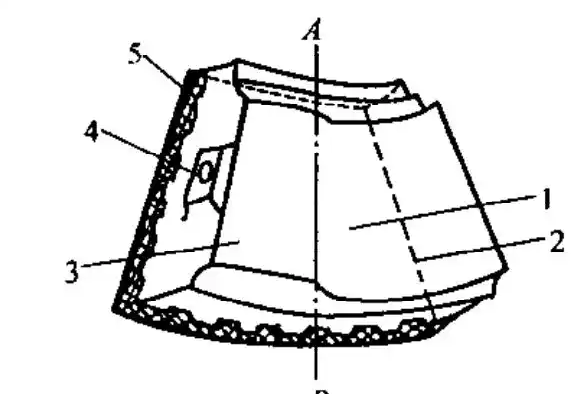

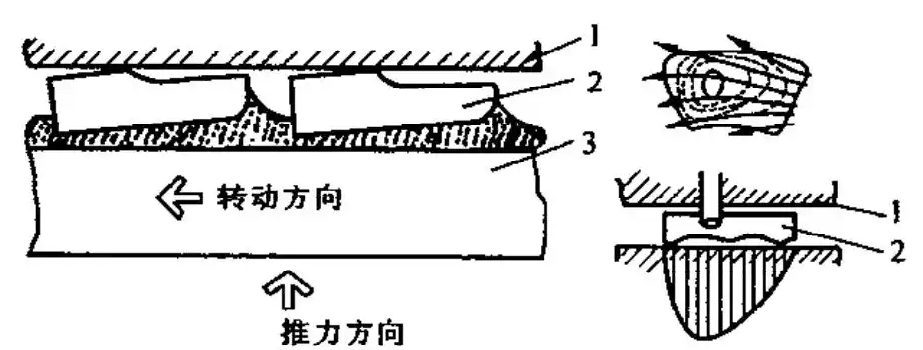

The thrust block is a critical component of the thrust bearing. While its structure may vary across different engine models, the operating principle remains consistent. Figure 3 presents a three-dimensional view of one thrust block design. It adopts a fan-shaped configuration. Workers cast white alloy 5 onto the working surface near the thrust ring and machined a fillet or chamfer at the oil inlet edge 2.

On the adjusting ring side, two surfaces (Surface 1 and Surface 3) are formed at different heights. The edge where these surfaces intersect serves as the working edge during operation, which contacts the working surface of the adjusting ring. Both sides of the thrust block feature a boss (4), which supports adjacent thrust blocks and aids in their positioning.

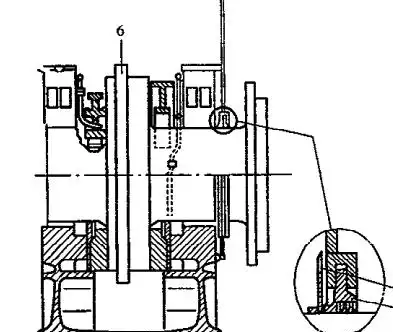

Under normal conditions, the thrust bearing operates under fluid dynamic lubrication. Refer to Figure 4 for details: Thrust block 2 deflects slightly around the support blade, creating a wedge-shaped space between the thrust block and the working surface of thrust ring 3. The thrust ring draws lubricating oil into this wedge-shaped space, thereby generating dynamic oil pressure.

The thrust force borne by the thrust ring is transmitted to the thrust block via hydraulic pressure, then transferred to the regulating ring 3 through the support blade. Figure 4 also illustrates oil flow patterns and pressure distribution across the thrust block’s working surface: As thrust increases, the clearance between the thrust block and thrust ring decreases, raising the oil’s dynamic pressure and consequently amplifying the transmitted thrust. Conversely, at excessively low rotational speeds, hydraulic pressure diminishes, potentially leading to semi-fluid film lubrication due to insufficient pressure.

Figure 5 shows a simplified diagram of a typical thrust bearing. The forward and reverse thrust blocks are positioned by pressure plates 6 and 7. When the thrust blocks are pressed together, gaps i1 and i2 remain at the pressure plates 6 and 7.

The combined clearance i1 and i2 must comply with specifications outlined in the manual. Operators can adjust the specific values by adding or removing shims at the pressure plate locations. This clearance ensures the thrust blocks can pivot freely around the support edge, guaranteeing normal thrust bearing operation.

The forward thrust block 3 rests against the forward adjustment ring 2, while the reverse thrust block 4 rests against the reverse adjustment ring 5. These adjustment rings play a critical role: they not only regulate the clearance between the thrust blocks and thrust rings but also adjust the axial relative position between the crankshaft and bearings.

Personnel measure thrust bearing clearance using two methods: First, firmly press the thrust ring onto the forward thrust block and measure the gap between the reverse thrust block and thrust ring with a feeler gauge. Second, allow the shaft to remain in a free state without axial force, measure the gaps at both the forward and reverse thrust rings with a feeler gauge, then add the two measurements to obtain the total clearance value.

The measured clearance must meet specification requirements. If non-compliant, technicians must adjust using the adjustment ring. In emergencies, technicians may temporarily insert shims behind the adjustment ring as an interim measure, replacing the adjustment ring during subsequent ship repairs.

When installing two rows of thrust blocks at the factory, the adjustment ring requires specific alignment: When the assembly clearance between the thrust ring and both forward/reverse thrust blocks is 1 (2), the centerline of the last crankpin nearest the thrust bearing must be offset toward the thrust bearing by a specified amount.

This compensates for thermal expansion of the crankshaft during operation, ultimately ensuring uniform axial clearance between each crank arm and main bearing to guarantee stable diesel engine operation.