Contents

1.1 Basic Definition and Characteristics

A one way bearings is a specially designed bearing that allows free rotation in one direction while providing significant resistance in the opposite direction, enabling one-way power transmission. This unique feature makes it indispensable in various industrial applications.

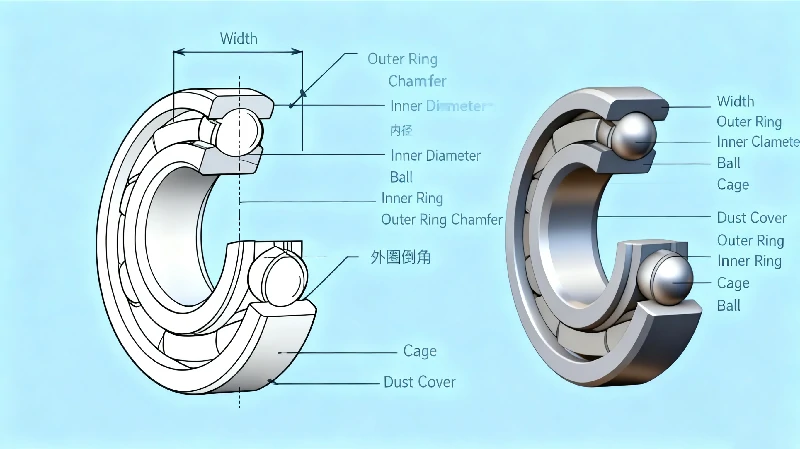

1.2 Structural Composition and One-Way Mechanism

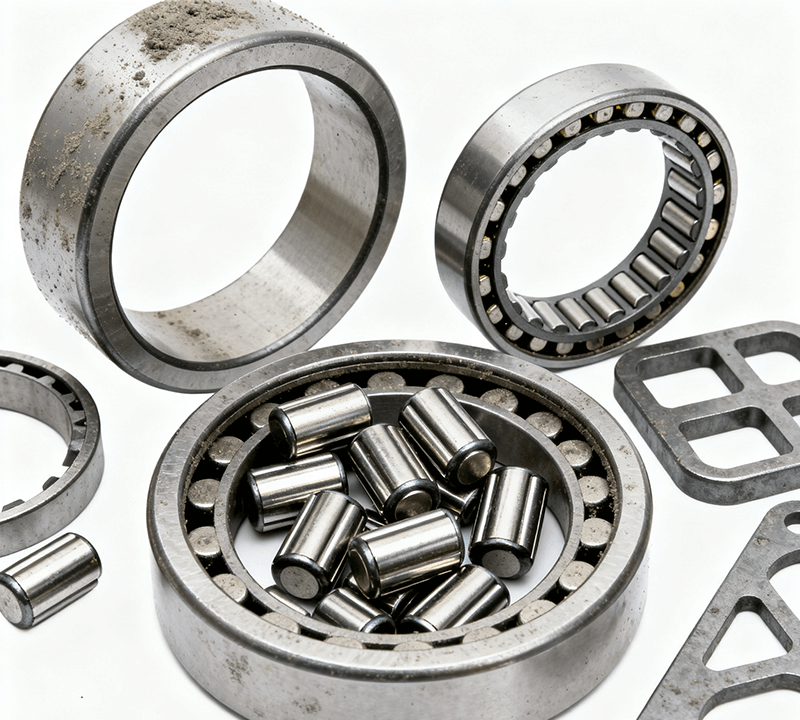

The internal structure of a one-way bearing typically includes components such as rollers, needles, or balls. These elements are arranged in a precise layout to achieve one-way rotation, allowing the bearing to adapt to diverse mechanical transmission requirements.

1.3 Core Design Highlights

The standout feature of this type of bearing lies in its rolling seat structure. When reverse rotation occurs, the rolling seat effectively prevents backward movement, ensuring stable operation in complex working environments.

1.4 Detailed Working Principle

The operation of a one-way bearing is based on a locking mechanism, typically implemented through ramp or wedge structures. Taking the ramp design as an example, the outer ring is a conventional cylindrical structure, while the inner ring is a specially designed ring with ramps. Additionally, the bearing includes rollers that maintain constant contact with both the inner and outer rings, along with corresponding spring mechanisms. These components work together to form a complete one-way transmission system. When the bearing rotates clockwise, the rollers move downward along the ramps, allowing ample space for smooth rotation. During counterclockwise rotation, the rollers encounter upward movement along the ramps, leading to restricted space and achieving self-locking.

2.1 Installation Methods

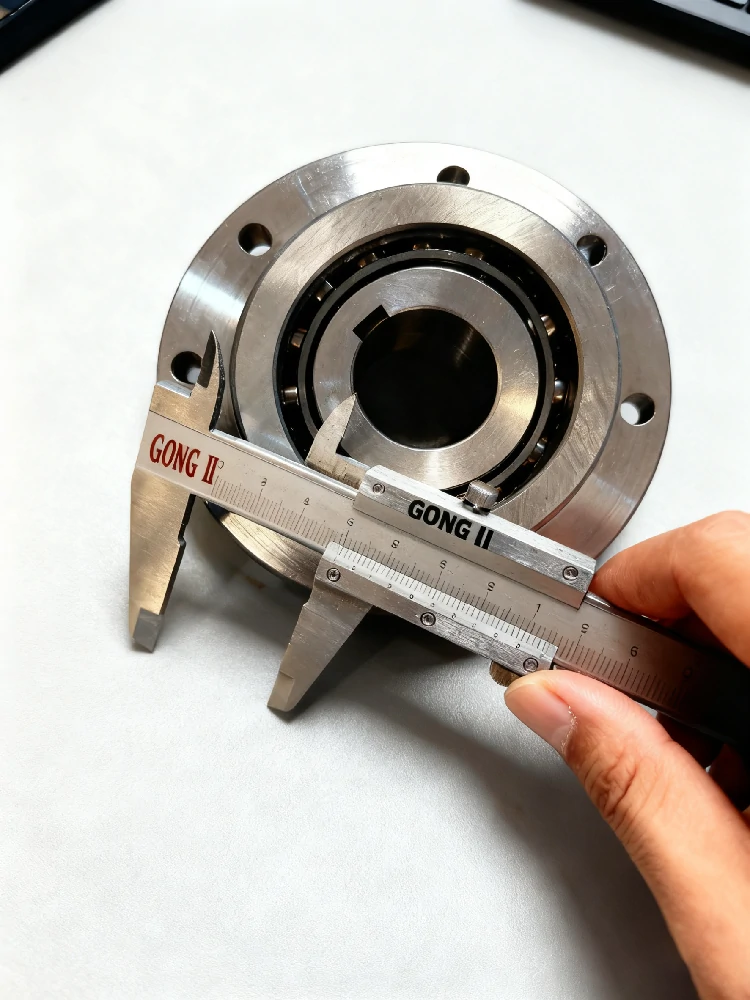

Depending on the bearing type and application conditions, either press-fit or heat-sleeve installation methods can be used. Press-fit installation can be performed using a press, bolts and nuts, or, when necessary, a hand hammer. Heat-sleeve installation involves heating the bearing in oil to expand it before mounting it onto the shaft. This method minimizes external force impact and allows for quick assembly.

2.2 Maintenance and Inspection Protocols

To ensure the proper functioning of one-way bearings, regular inspections and maintenance are essential. Key areas to monitor include unusual noises and signs of wear. Standard maintenance procedures involve visual inspections, sound identification, and professional instrument testing. During disassembly and repair, it is crucial to apply pulling force only to the bearing rings and never to the rolling elements.

One-way bearings play a vital role in numerous mechanical devices, including textile machinery, printing equipment, automotive manufacturing, and household appliances. Their application effectively prevents reverse rotation and enhances operational efficiency. With ongoing technological advancements, the design and performance of one-way bearings will continue to improve, paving the way for broader applications and development prospects in the future.

Square bore bearings find extensive applications in manufacturing. Below we highlight their key features and uses. Str…

Tungsten carbide ball bearings, commonly known as tungsten steel balls, are spherical and roller bearings manufactured…

As a core component of heavy-duty equipment such as dock conveyor belts, the selection and maintenance of self-aligning…