Common Bearing Failures and Their Prevention, If you’ve ever hunched over a greasy machine body during a rotating three-shift weekend, you’ll know this for sure: bearings are no toys. This tiny component has a knack for causing major headaches. And you’ll inevitably find yourself asking, “Why is this thing broken again?”

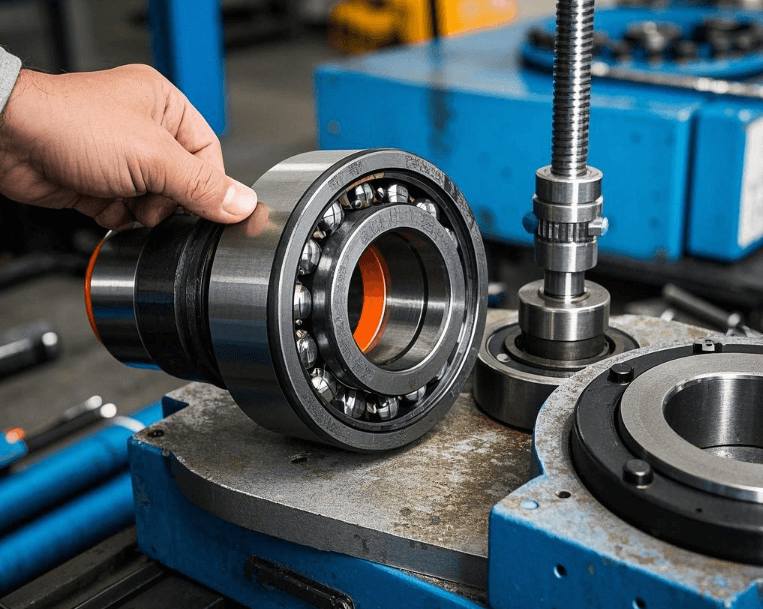

Most of the time, the problem lies in how it was reinstalled—not as a precision mechanical part, but like shoving a piece of gummy candy back into place.

Bearing Failures and Their Prevention, Let’s take a look at common bearing failures we see every day—even those that baffle the most experienced maintenance workers.

Inhalt

You don’t need a degree in nuclear physics to figure this out: if your bearing is overheating, it’s either installed too tightly or inadequately lubricated. A typical mistake is using a hammer to pound the inner ring onto the shaft, as if you’re loosening a pipe. Then we wonder why tiny cracks form on the inner ring and the lubricant oozes out like thick soup.

Prevention: Use specialized tools (e.g., Simatool, Simatherm) for installation, and tighten with precise, standard torque—no need to rely on brute force from your biceps.

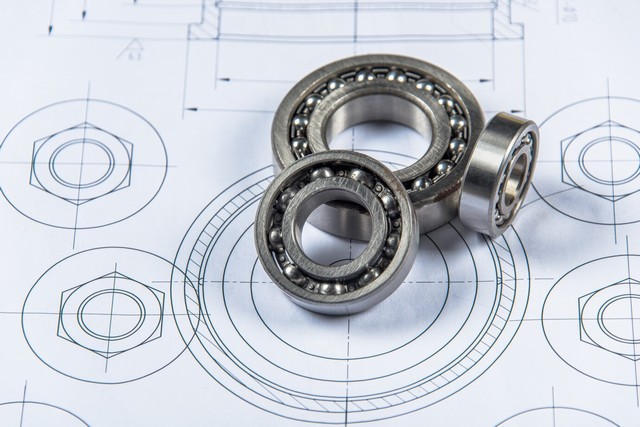

Sticking oily fingers into the grease is like putting a sterile needle back into mud. Dust, rust, and metal shavings—all of these can work their way into the bearing, increasing friction drastically. The bearing’s mirror-smooth raceway ends up looking as rough as if it’s been coated in plaster.

Prevention: Keep the installation area clean, wear gloves, and never use an air compressor to blow air at bearings on the floor—otherwise, you’ll be in real trouble.

Often, the bearing wobbles on the shaft like it’s dancing disco. Sometimes, it’s so tight that you have to bend it forcefully to remove it—trapped tight. Either way, the result is the same: premature failure. One gets worn down, the other cracks, but both end up broken.

Prevention: Micrometers and other measuring tools shouldn’t be overlooked. Use a professional workbench and follow ISO standards strictly—don’t rely on “feel” by pushing with your stomach or forcing it. This isn’t installing drywall; you can’t just say “that’s good enough.”

This is a failure many people don’t anticipate. If a motor has poor insulation or faulty grounding, tiny electrical arcs may form in the bearing. These arcs burn the rollers and raceways, and eventually, the bearing ends up in the trash.

Prevention: Use insulated bearings or install grounding carbon brushes for the motor.

In machine shops, it’s common to see mechanics pounding the inner ring of a bearing onto the outer ring. That’s how a perfectly good bearing gets turned into a hunk of forged iron.

Prevention: Apply force only where it’s needed—for the inner ring, apply force to the shaft; for the outer ring, apply force to the bearing housing. The Kernkomponenten in the middle are the “soul” of the bearing—never damage them.

Bearing Failures and Their Prevention, Bearings demand no carelessness. Those who install them precisely, in clean environments, and with professional techniques rarely need to replace bearings. But for those who think a hammer can fix everything, there’s always a replacement bearing waiting in the warehouse—after all, if you break them quickly, you’ll need to replace them just as fast.