Hängelager sind wichtige Stützkomponenten in modernen Industrieanlagen, insbesondere in Schüttgutförderanlagen wie Schneckenförderern, Becherwerken und Getreideumschlaganlagen. Für industrielle Einkaufsleiter, ein eingehendes Verständnis der Struktur solcher Lager, Materialauswahl, Installation und Wartung Punkte, nicht nur zur Verringerung der Ausfallrate der Ausrüstung, sondern auch erheblich verbessern die Professionalität und Effizienz der Kaufentscheidungen. Dieser Artikel wird aus einer Vielzahl von Perspektiven, eine umfassende Interpretation der Funktion der Aussetzung Lager, Klassifizierung, Anwendungsszenarien und Auswahl-Leitfaden werden.

Die Aussetzung Lager ist ein mechanisches Bauteil, das zur Lagerung der rotierenden Welle in Systemen wie Schneckenförderern verwendet wird. Es trägt dazu bei, die Ausrichtung der Welle beizubehalten, Vibrationen zu dämpfen und eine reibungslose Rotation zwischen den Förderabschnitten zu gewährleisten. Je nach Belastung, Temperatur und Verschleiß gibt es verschiedene Arten von AufhängungslagernDazu gehören solche aus Holz, Bronze und Kunststoff sowie geteilte Ausführungen.

Als Nächstes werden wir die wichtigsten Funktionen, Typen, Werkstoffe und industriellen Verwendungszwecke von Traglagern analysieren, ebenso wie Tipps für die Auswahl des richtigen Traglagers für Ihr System.

Inhalt

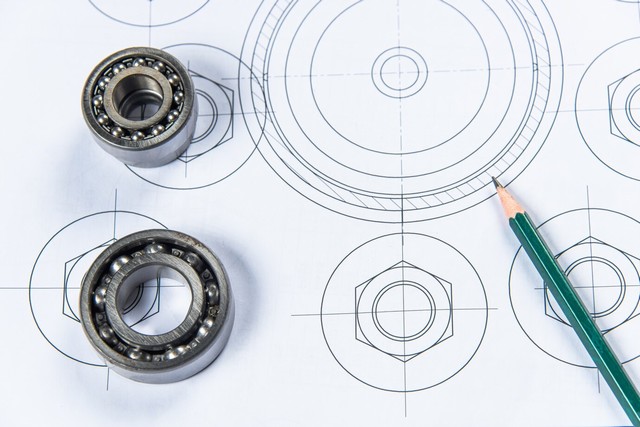

Aufhängung Lager sind so konzipiert um eine stabile Lagerung der Welle sowie eine leichte Drehbarkeit und Wartung zu gewährleisten. Ein typisches Hängelager besteht aus den folgenden Teilen:

Gehäuse: das Gehäuse zur Montage und Befestigung, in der Regel aus Gusseisen oder Stahl.

Schindeln: Auswechselbare Teile, die in direktem Kontakt mit der Welle stehen und die Last tragen, in der Regel aus Polymer, Bronzelegierung oder Gusseisen.

Dichtungen: verhindern das Eindringen von Staub und Verunreinigungen in das Innere des Lager und schützen die Schmierung System.

Abschmiervorrichtung: Ausgestattet mit Schmiernippeln oder Öllöchern, um die Wartung zu erleichtern.

Montagewinkel: Befestigt das Lager am Förderband oder am Geräterahmen, um einen stabilen Betrieb zu gewährleisten.

Dieser strukturelle Aufbau ermöglicht die Aufhängung Lager, um der Belastung standzuhalten der Zwischenwelle und ist gleichzeitig einfach auszutauschen und zu warten, was sie ideal für Hochleistungsanwendungen wie Schneckenförderer macht.

Aufhängung Lager werden hauptsächlich zur Abstützung von langen Förderschnecken oder Zwischenwellensegmenten in Schneckenfördersystemen verwendet und spielen eine wichtige Rolle bei der strukturellen Abstützung im industriellen Materialtransport. Wenn die Welle eines Förderers lang ist, kann das Fehlen einer wirksamen Abstützung in der Mitte zu einem Durchhängen oder einer exzentrischen Bewegung führen, was die Effizienz der Anlage verringern und auch zu vorzeitigem Verschleiß oder sogar schweren Schäden an der Anlage führen kann.

Zu ihren Hauptaufgaben gehören:

Verhinderung des Durchhängens oder der schlechten Ausrichtung von Wellen zur Stabilisierung der Struktur.

Reduzierung von Wellenschwingungen und Vibrationen für einen reibungslosen Betrieb.

Verlängern Sie die Lebensdauer des Systems und reduzieren Sie die Wartungshäufigkeit.

Sie gewährleisten einen sicheren Betrieb unter schweren Lasten und verhindern Ausfälle in der Mitte des Systems.

Sie sind in den folgenden Branchen weit verbreitet:

Schüttgutfördersysteme (z. B. Gurtförderer oder Schneckenförderer).

Bergbau und Steinbrüche (für Umgebungen mit hohem Verschleiß).

Landwirtschaft und Getreidesilos (z. B. Schneckenförderanlagen in Silos).

Zement- und Betonmischanlagen (hohe Beanspruchung, staubige Umgebung).

Lebensmittelverarbeitende Industrie (erfordert FDA-konformen Edelstahl für die Hygiene).

Entscheidend ist die Auswahl und Aufhängungslager einbauen je nach Wellendurchmesser, Last, Betriebstemperatur und Umgebungsbedingungen. Bei unsachgemäßer Dimensionierung oder Installation können sich Förderwellen unter schweren Lasten durchbiegen, festfressen oder sogar brechen, was zu einem Systemausfall führt.

Bei einer Förderschnecke ist die Aufhängung Lager ist ein Schlüssel Bauteil, das in der mittleren Aufhängungsposition montiert ist, um die längere Zwischenwelle zu stützen und ihre stabile Drehung zu gewährleisten.

Wenn die Länge des Förderbandes 3 bis 4 Meter überschreitet, müssen mehrere Aufhängungen Lager werden oft eingebaut um die Last zu verteilen und einen reibungslosen Betrieb der Anlage zu gewährleisten. Diese Lager sind in einer "hängenden" Konfiguration montiert, die kompakt und einfach zu installieren und zu warten ist.

Zu den wichtigsten Funktionen von Traglagern in Schneckenförderern gehören:

Stützt den mittleren Teil des Schafts und verhindert so Biegen und Wackeln.

Verringern Sie die Reibung und verbessern Sie die Effizienz der Beförderung.

Verlängern Sie die Lebensdauer Ihrer Geräte und reduzieren Sie die Ausfallraten.

Achten Sie auf die richtige Zentrierung und die gleichmäßige Drehung der Schraubenblätter.

Da sie häufig in staubigen, heißen oder korrosiven Umgebungen eingesetzt werden, sind die Lager in der Regel mit austauschbaren, verschleißfesten Ausgleichsscheiben und Schmiersystemen ausgestattet, um eine stabile Leistung unter rauen Bedingungen zu gewährleisten.

Die Auswahl des richtigen Aufhängungslagers ist entscheidend für die Stabilität und Langlebigkeit Ihres Förderers. Hier sind einige wichtige Empfehlungen:

Wellendurchmesser: Es ist wichtig, den Innendurchmesser des Aufhängungslagers auf die Größe der Zwischenwelle des Förderers abzustimmen, wobei die Lastanforderungen zu berücksichtigen sind. Je länger die Welle und je schwerer die Last, desto stärker muss die Tragkonstruktion sein.

Materialverträglichkeit: Die Arbeitsumgebung variiert von Industrie zu Industrie, so dass die Lagerwerkstoffe entsprechend den spezifischen Bedingungen ausgewählt werden müssen. Für hohe Temperaturen, feuchte, korrosive oder staubige Umgebungen werden korrosionsbeständige Materialien (z. B. Edelstahl oder Kunststoff-Wellenkacheln) und Dichtungsstrukturen empfohlen. Für lebensmitteltaugliche Anwendungen werden Bronze- oder UHMW-Kunststoffmaterialien empfohlen.

Schmierung: Wählen Sie Aufhängungslager mit Schmiernippeln oder Ölbechern für eine einfache Wartung. Für schwer zugängliche Bereiche sind selbstschmierende Materialien oder versiegelte Konstruktionen möglicherweise die bessere Wahl.

Verschleißfestigkeit: Die Verschleißfestigkeit von Radaufhängungslagern wird hauptsächlich durch das Material der Achswelle bestimmt. So bieten beispielsweise Bronzelegierungen eine bessere Verschleißfestigkeit bei hohen Temperaturen und schweren Lasten. Weitere Optionen sind Hochleistungskunststoffe (wie Polyethylen mit ultrahohem Molekulargewicht) und Gusseisenschindeln.